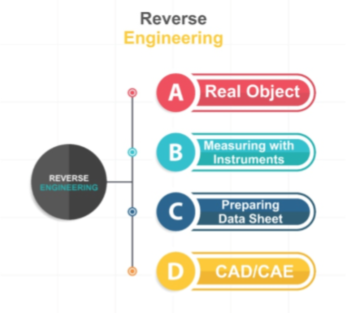

Reverse Engineering using CAD is the process of creating a three-dimensional virtual model of an existing physical part.

This process needs hardware and software: hardware such as coordinate measuring components to measure physical objects, and software to reconstruct objects as 3D models.

The course teaches the ways to getting data preparing the data sheet, manipulate the tools, modify 3D data. The course also equips students to analyze a product's structure, function and operation, and the applications of Measuring components, how to handle and measure in equipments and how to design in any modeling software. Students are offered projects with expert guidance.

75 Hours

Introduction to Reverse Engineering

Introduction to Reverse Engineering

What is DFMA

What is DFMA

The Basics of Reading Engineering Drawings

The Basics of Reading Engineering Drawings

Any modeling software (Solid or Surface)

Any modeling software (Solid or Surface)

Measuring equipments, least count of devices and error checking How to handle and measure the components

Measuring equipments, least count of devices and error checking How to handle and measure the components

How to prepare the data sheet

How to prepare the data sheet

Data sheet preparation

Data sheet preparation

3D modeling (solid or Surface in any software)

3D modeling (solid or Surface in any software)

Product analysis (CAE)

Product analysis (CAE)

Certified instructors

Industry centric curriculum

Students will be offered with work book

Industrial based training

Industrial Certification

Opportunity for internship / placement assistance

Door No. 700/140, First Street Extension, Dr Rajendra Prasad Rd, Gandhipuram, Tamil Nadu 641012