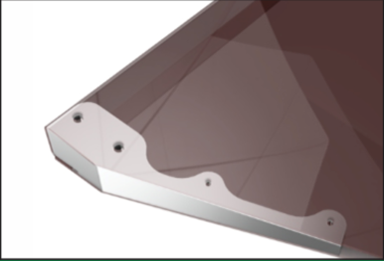

Modern continuous rolling mills produce large quantities of thin sheet metal at low cost. A substantial fraction of all metals are produced as thin hot-rolled strip or cold-rolled sheet; this is then formed in secondary processes into automobiles, domestic appliances, building products, aircraft, food and drink cans and a host of other familiar products.

Sheet metals parts have the advantage that the material has a high elastic modulus and high yield strength so that the parts produced can be stiff and have a good strength-to-weight ratio. A large number of techniques are used to make sheet metal parts.

This book is concerned mainly with the basic metal farming process that underlie all of these methods, rather than with a detailed description of the overall processes, but it is useful at this stage to review briefly the most common sheet forming techniques.

75 Hours

Introduction to sheet metal

Introduction to sheet metal

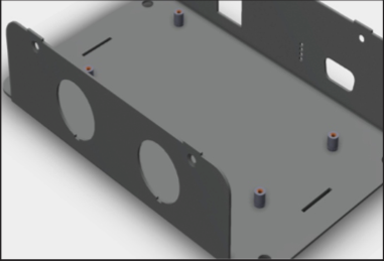

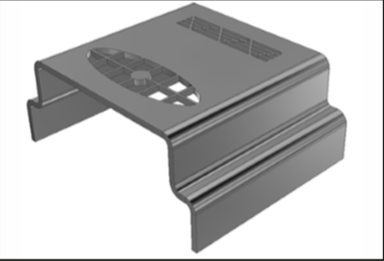

Application of sheet metal

Application of sheet metal

Material properties

Material properties

Types of gauges

Types of gauges

Tolerances

Tolerances

Types of sheet metal process

Types of sheet metal process

Bending Calculations

Bending Calculations

Bending operations

Bending operations

Cutting operations

Cutting operations

Sheet metal drawing with calculations

Sheet metal drawing with calculations

Rules on sheet metal manufacturing process

Rules on sheet metal manufacturing process

Design with any modeling software

Design with any modeling software

Certified instructors

Industry centric curriculum

Students will be offered with work book

Industrial based training

Industrial Certification

Opportunity for internship / placement assistance

Door No. 700/140, First Street Extension, Dr Rajendra Prasad Rd, Gandhipuram, Tamil Nadu 641012